Lacquer information

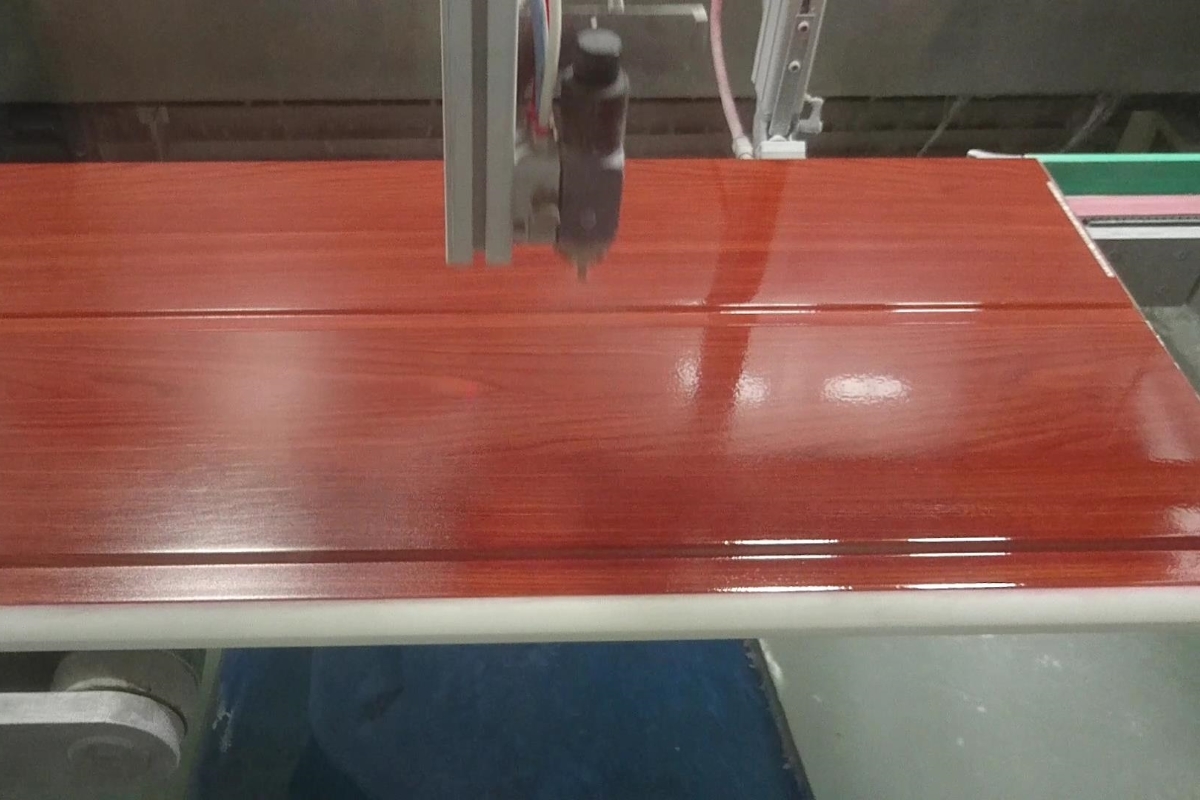

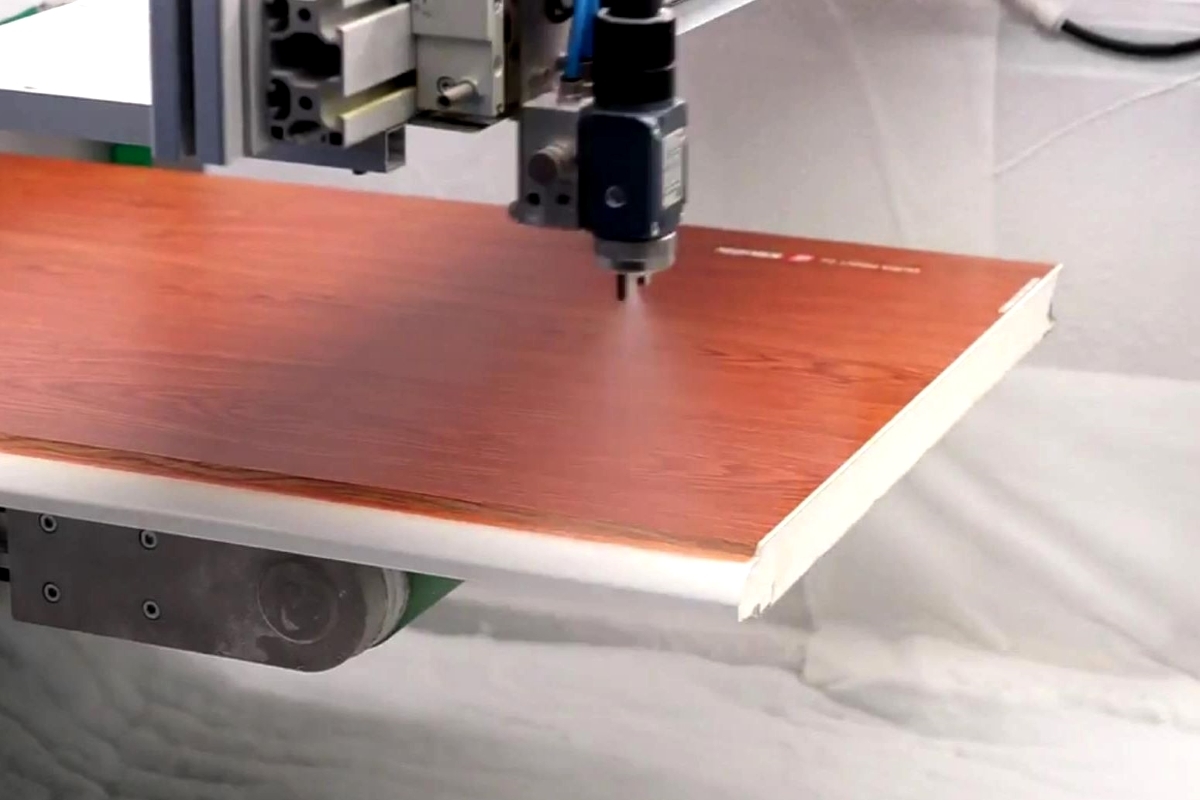

Panels are sprayed with a protective automobile grade lacquer after printing. Lacquer provides superior resistance to corrosion, fading and scratches. It provides the opportunity to give customers a longer warranty period against fading and corrosion.

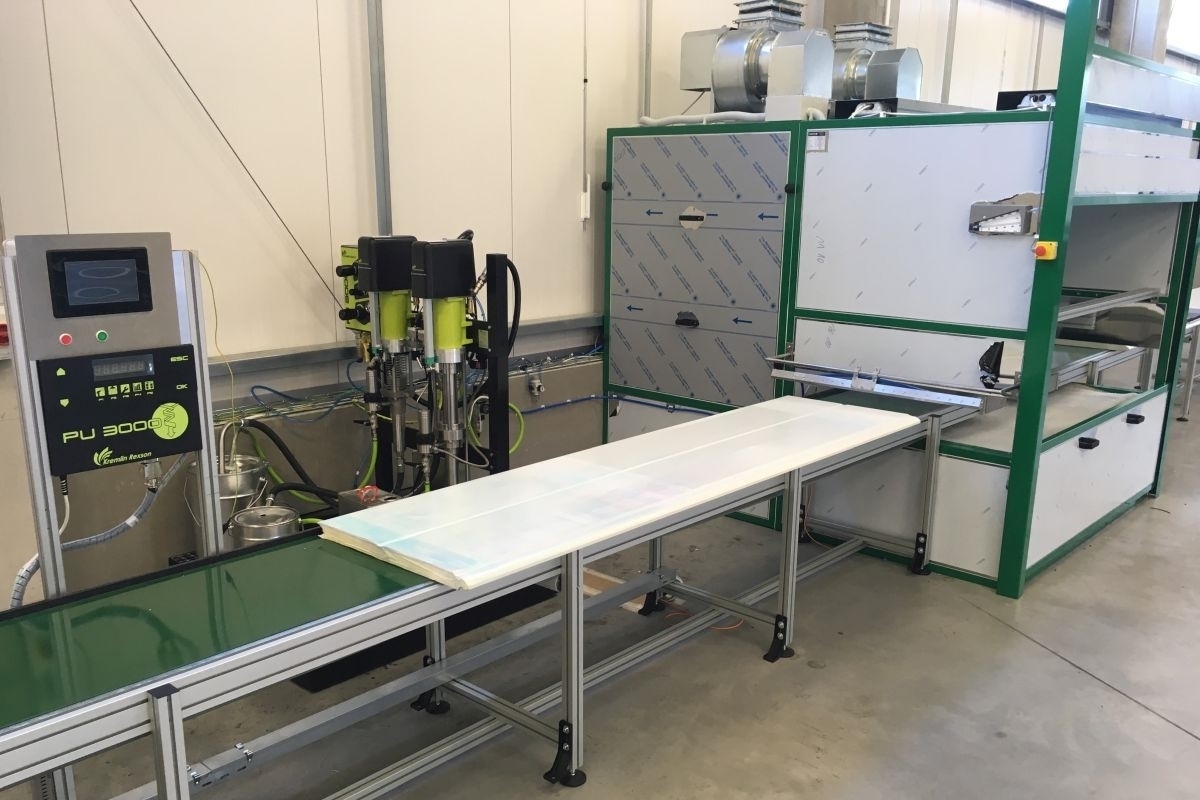

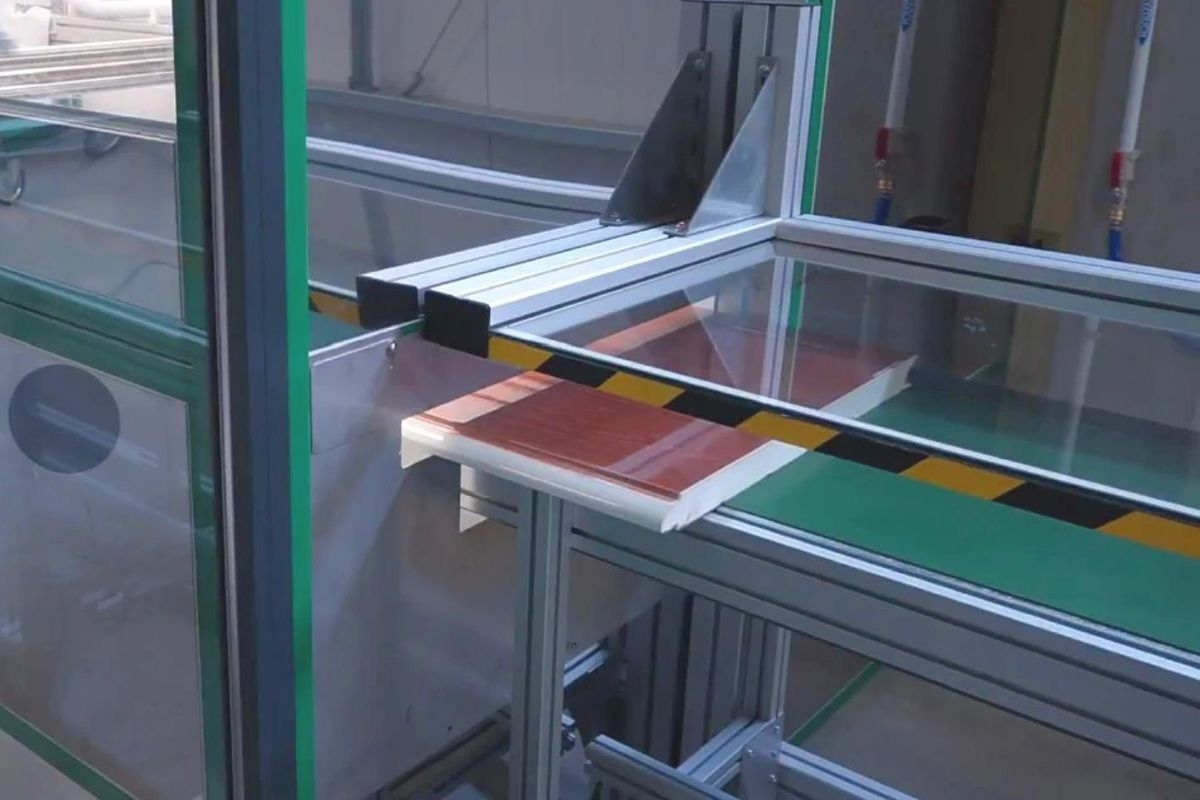

After lacquer application, panels are transferred to the drying room and automatically loaded onto racks. Drying time for lacquer is 30 minutes to 6 hours, depending on the type of lacquer, thickness and drying room temperature.

axbox lacquer

- Digital inkjet printing requires a protective coating for exterior use

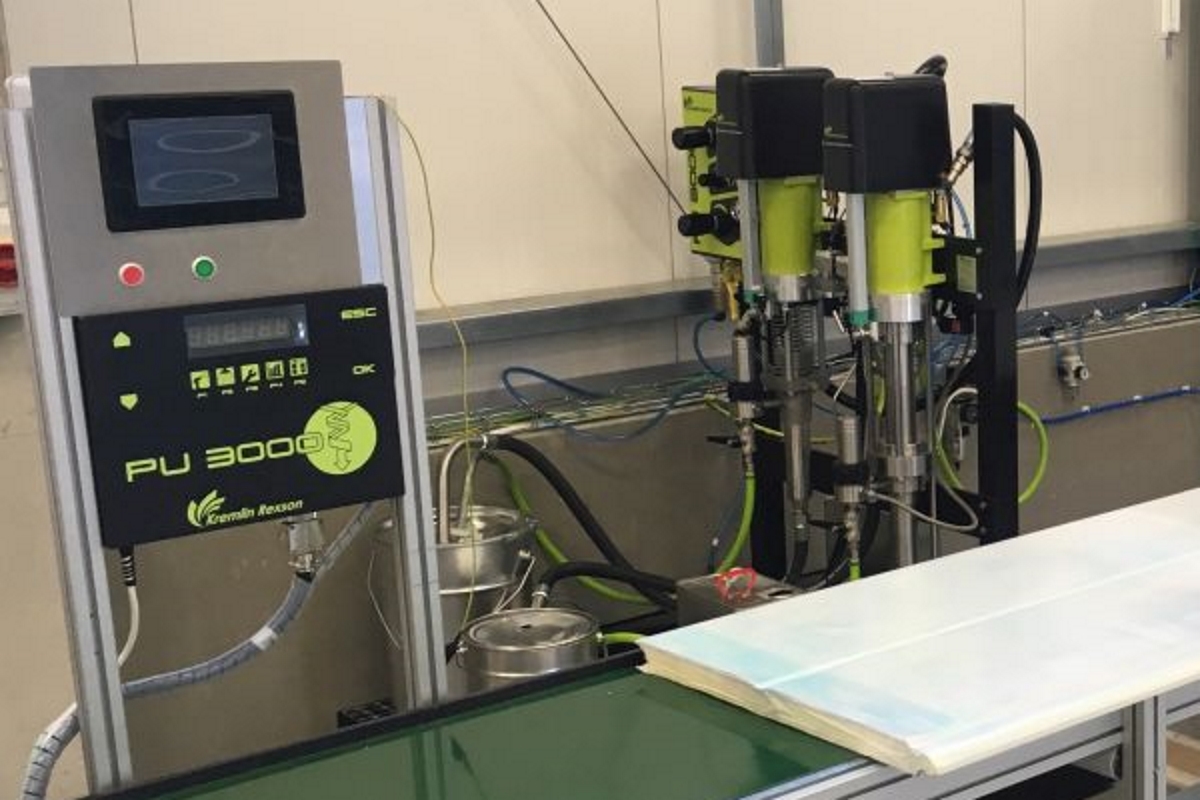

- Polyurethane automobile grade lacuqer is sprayed on the exterior

- Fully automatic spray application

- Lacquer has a matt finish

- The lacquer, after drying is approximately 50 microns thick

- Lacquer provides superior resistance to fading, corrosion and scratches

- Possible to offer a longer warranty for corrosion resistance and door appearance

- After spray application, panels transfer on a conveyor system to the drying room through a transfer hatch for automatic loading onto drying racks

axbox lacquer: additional uses

- The lacquer box may be used for standard door panels or other building

materials to make additional income - Production rate: up to 1.200 lm per hour

- Lacquer standard paint finish door panels for improved resistance against to corrosion, fading and scratches. Longer warranties are possible to give to customers.

- Lacquer the interior side of panels for special industrial door installations:

- Car washes

- Any door that requires stainless steel hardware

- Doors frequently cleaned on the interior, such as food

processing or chemical factories

- Lacquer exterior building material panels ("may require"additional equipment or modifications)